When troubleshooting power wheels, most of the faults you’re likely to encounter are mechanical and solvable, with only a few of them requiring attention from a professional.

Here’s a list of the common problems we tackled in the article:

- The car only has no reverse

- Car won’t move / no sound from gears

- Motors overheat

- The car shuts off then restarts in 30 seconds

- Batteries blow fuses with upgraded motors

- The power wheel is making a grinding noise

- Power does not reach where needed

- How to test the throttle or foot pedal switch

- Motor and controller issues

- The power wheel tires keep on skidding

- 6V power wheel is not fast / strong enough

- The Power Wheels battery is charged but not working.

- The vehicle runs sluggishly.

- Only one rear wheel spins when pedal is pressed

- Vehicle only runs in low speed

- The vehicle won’t run without a push

Table of Contents

How Do You Troubleshoot a Power Wheel?

Like any other mechanical unit, power wheels are prone to developing operational problems.

Troubleshooting power wheels involves checking out for any faulty operation and making necessary adjustments to get everything back to normal. Of course, a successful troubleshooting process must end in a viable solution.

Here are the possible problems you’ll encounter with your power wheels.

The Car Has No Reverse

It is crucial that a car comes with a reverse mode for convenience and safety. If the power wheel is faulty, it may only be able to move forward, with no reverse mode.

In reverse-enabled power wheels, you should check the wires to the power wheel’s motors, for the motor responsible for reverse movement may have lost a wire. If that’s the case, the motor needs to be replaced, since the wire can’t be repaired.

If you have a shifter assembly, it might be possible that one of the switches has gone bad. The same case applies to dashboard switches. Check out for the possibility of the two. Good thing they can be replaced since they are inexpensive and available.

Car Won’t Move / No Sound From Gears

That is one problem you’ll frequently encounter. Here’s how you diagnose the problem;

- Using a voltmeter, check your battery reading. It should read at least 10Vwhen dead and 14V when charged.

- Ensure you have a powered outlet where your charger should be plugged.

- Check the switch under the power wheel’s pedal. Most footboard assemblies are press-fit into place but can be freed with a straight-head screwdriver. In any case, you find the wire harness corroded, you may get replacements from the market.

- Check the wires connecting the motors. Having two wires going to each motor, make sure none has come off. If they have, then they cannot be repaired.

- Check the motors too. Battery power may be sufficient enough and all connections perfect, but the motors might be faulty. Therefore, inspect your motors for any faults. If the problem lies within the motors, then you’ll have to replace them.

Motors Overheat

Concerning the battery required, stock motors are designed for batteries up to 12v SLA. Lithium batteries are discouraged for use in ride-on(s) because they have a 5x higher discharge rating than SLA batteries.

With no clutch to absorb all of that extra power, motors have no choice but to overheat to lose that excess energy.

Performance motors need the power wheel’s motor brushes ‘seated’ to the commutator under a small load. That is done by raising the car’s back in the air and running it at low speeds for the time listed on the manufacturer’s user manual.

Failure to break them in causes excessive sparking/arching in the motor brush. That damage is unrepairable.

Did you check that the pinion gear is the right pitch and tooth count for the gearbox? The 7R is the only gearbox that can change tooth counts.

On the gearbox housing, you’ll find printed information on the range your 7R gearbox can handle. Using an enormous pinion gear will cause the mesh to be super tight, resulting in a strain on the motor.

The motor will fail, or the first gear will strip or melt. The tooth shape is indicated on the pitch, and it can never be changed.

Again, modified tires will result in the overheating of motors. The closest thing the car has to a clutch is the spinning tire. The increase in weight from adding traction or rubber results in strain on the motors and gears.

Moreover, changing to a larger wheel diameter tire changes the car’s final drive gear ratio and may overheat the motors. The larger diameter tires should be countered with a relatively more minor pinion.

Therefore, if you need to replace your tires, go for the ones with the recommended wheel diameter, like something of the ordinary changes the drive gear ratio and brings about overheating.

In addition, overheating of the motors may be due to an overload in weight on the power wheel.

When the tires are pressed hard on the ground from a heavy weight, the resultant force causes the motors to overwork to keep the power wheel in motion. Therefore, you should confirm with the user’s manual for the maximum weight limit of the car and work by it.

Shuts off Then Restarts in 30 Seconds

Your power wheel may shut off when its stock batteries get old or may have an increased charge draw either from a binding drivetrain or modified motors.

The internal 30 amp circuit breaker pops and then resets. To minimize chances of occurrence of the situation, make sure the wheels turn freely, and the rear axle is perfectly straight.

Check the wire connections too. You might have poorly insulated wires that are keeping contact.

Lighten the vehicle load and avoid the tall grass. Switch to batteries that use a 40amp fuse and run 30% longer. That is often needed with 24-volt systems or 775 motors.

Batteries Blow Fuses With Upgraded Motors

Sometimes, after upgrading your motors, you may notice that your car starts blowing fuses. Fuses are created to either work or not. If they fail or blow out, you will have no power traveling through them, and nothing will work.

That happens mostly in areas where power needs to make a turn, mostly in foot pedal switches and shifters. Switches slowly lose their ability to handle increased loads as they age. Fortunately, switches are easily replaceable, and that shouldn’t be much of a worry.

However, fuses may also be likely to pop in the areas you have made foreign connections.

Here are some remedies to try out in such an event.

- Replace the shifter switches whenever the shifter handle feels loose.

- When the copper wire blackens, you’ll need to replace that section of the wire harness. You’ll need to inspect the foot plunger switch to spot the change in the copper wire color.

- Testing all the switches for resistance should be done with an ohmmeter. You may find a good-looking switch on the outside but faulty on the inside. Have some extra switch spares. They are always cheap and convenient in such emergencies.

- In an event where you spliced wires in a previous repair job, then check to make sure you did it correctly. You can take the spliced wires apart and solder them.

- You should always prefer hand tightening the motors. Tightening them using a power drill brings out excessive pressure on them and may lead to breakages. If you used a power drill, take the motors out and do it again with your hand. Don’t forget to put thread locks on the screws.

- Check your rear axle for bends by rolling it on a flat surface. Even the slightest bending in the axles can shred final gears, third gears, and gearbox housings needs to be corrected.

- If your batteries are old, find a way to replace them instantly. Again, if you’re using stock power wheel batteries, take note that they only have a 30 amp circuit breaker. They degrade with time and can only handle lesser power. If you’re planning to replace your batteries, don’t go for those rated above 12 amps.

- If you’re running rubber tires, consider taking them off. The spinning wheel is the only car’s clutch. Without it, you’ll most probably blow fuses, gears, motors, even your wallet!

The Power Wheel Is Making a Grinding Noise

Gearboxes usually fail because of an external influence. That is caused by a stripped gear or one of the wheel drivers. And if one gear is stripped, then the other isn’t far behind.

It will therefore be better if the replacement is done to both. Here are ways in which gearboxes may sustain damages.

- If the gearbox housing behind the final drive gear melts, that can be caused by uneven or too much pressure pushing against the final drive gear. Three significant causes are modified tires, bent axle, or damage to the frame where the axle mounts.

- Melted gearbox housing at the power wheel’s first gear shaft. That can be caused by a lack of grease on the shaft, old grease, or debris in the gearbox.

- Stripped first gear. That is the weakest link and the first thing to let go of when adding more power. If the motor wasn’t bolted tightly to the gearbox, then the gear teeth may be stripped at an angle.

If you find that each tooth is half-stripped, it means that the pinion wasn’t centred over the first gear. If few teeth are missing or broken, there might have been a sudden jolt to the gear area. If all of them are missing, then it could be any of the above causes.

If you want a permanent solution, you ought to replace the first gear and pinions with steel substitutes. - Broken teeth on the other (2nd, 3rd, or final) drive gears. That may be brought about by a sudden jolt to the gearbox.

- Pinion gear stripped – That is as a result of the pinion gear being of the wrong material or shape. If you’re using a steel first gear, you ought to use a steel pinion, too, not any other metal.

Make sure that the gear’s pitch is 32. The pinion’s shape is essential in syncing to the first gear’s teeth, and therefore it should always be intact.

There’s significant variation in the shape of the pinion between any two brands, and it is advisable not to alter the initial shape.

Power Not Reaching Where Needed

Using a simple voltmeter, you may solve the problem by checking the power supply and identify the issue without struggling a bit. Check the circuitry connection of the power wheel and make sure all switches and fuses are intact.

If you manage to identify the disconnect and repair it, then you expect power to move to the forward and reverse switches and the pedals. Power is also transferred to the motors and every aspect of the power wheel that needs the power to work.

- How to test the throttle or the foot pedal switch.

If you suspect a problem with the throttle or foot pedal switch, you will need to use a multimeter for the checkup. Disconnect the paddle switch and use a paperclip to test the connection.

If the motor starts immediately after you have jumped the connection, you now can be sure the problem lies with the pedal switch.

If, in any case, it doesn’t jump, you could be facing an electric issue and may need a replacement motor. There is also a chance that the power wheel’s foot pedal is stuck.

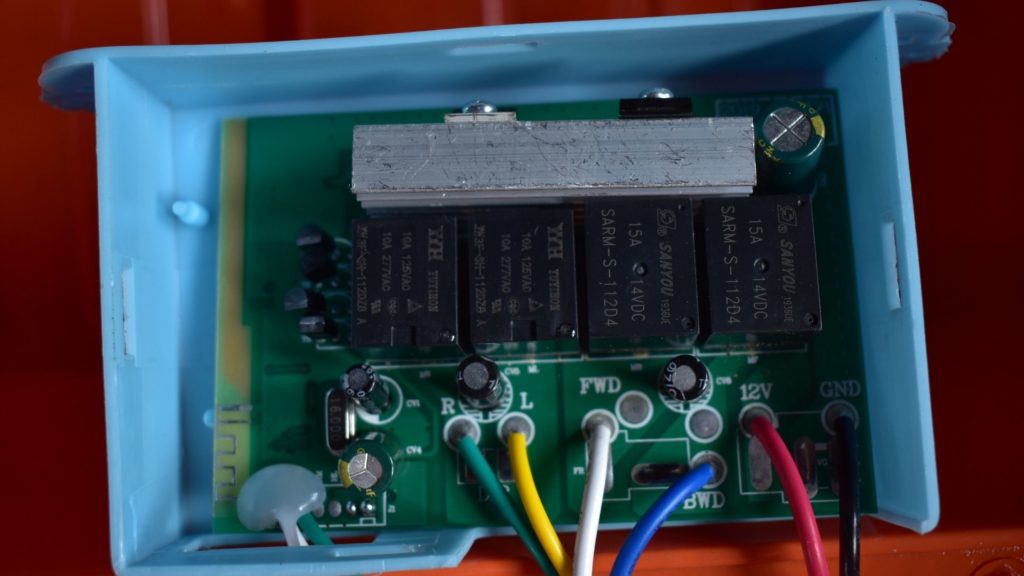

Motor and Controller Issues

Before checking the motor and controller, ensure that the switches and batteries are working in good condition. If you come across a clicking sound, then the problem could be within the controller’s motherboard.

If it’s more of a grinding sound, the chances are that the gears in the gearbox are ground down or stripped, as the stock ones are only plastic. That may come after you upgrade your battery but forget to upgrade your gearbox.

You can also test the performance of the same using a voltmeter, but you’ll need first to disconnect the motor and controller.

You’ll need to hook the motor to a 6V or 12V and make sure it’s turning. There’s little chance of the motors going bad since they’re designed to work for years.

If you are going to do an upgrade, you’ll need to do it to both the battery and tire to decrease the chances of overheating the motor.

The Power Wheel Tires Keep Skidding

Power wheels mostly come with plastic wheels that bear little to no traction. After a few days of using them, the tires may lose all traction, and your kid will be having trouble moving around.

You can solve this problem by installing rubber tires that are readily available on the market. However, there are several ways to ‘improvise’ rubber tires on power wheels, and they include;

- Getting aftermarket rubber bands and wounding them around the power wheel’s tire for increased traction

- Using flex seal liquid or spray. Both provide a rubber-like substance on the plastic ride-on tire, which effectively enhances the traction of power wheels.

Again, advise your kid to keep off the grass and slippery surfaces, and to always drive carefully and slowly in such, if it is compulsory to do so.

6V Power Wheel Is Not Fast or Powerful Enough

If your power wheel runs on a 6V battery, it is probably not as fast and strong as a 12V powered one. If you need to make your 6V quicker and more robust, you’ll need to replace the 6V battery with a 12V one.

Of course, there are few modifications you need to perform so as not to blow fuses here and there, including getting a step-down. After successfully installing the 12V battery, you’ll realize that the power wheel becomes faster and more robust.

Power Wheels Battery Is Charged but Not Working

The one question you should ask yourself is how long the battery has stayed dormant. If your ride-on was left to sit out for a long time without charging, then that’s a strong contender for your problem.

When a 6V or 12V battery is charged and left to sit out for long, it starts to drain itself. Once you pick it from the shelf and connect it to a charger, the charger might not detect the battery and might not dispense any charge.

Well, the best solution for this is that you should purchase a replacement battery. There are several of them in the market that come at a reasonable price.

However, you must be sure to adhere to the guidelines that come with the battery, especially concerning the length of the period the battery should stay without being charged.

In addition, to prevent an occurrence of such a problem, make sure you’ve fully charged the battery before you store it and always charge it within shorter intervals to keep its cells alive.

The Vehicle Runs Sluggishly

If the power wheel appears to operate sluggishly, these are the most common problems you might encounter and their possible solutions.

- Undercharged battery – Check on your battery-charging approach. A new battery should be charged for a minimum time of 18 hours before it can be used.

After that, you’ll need to be recharging the battery for at least 14 hours before use. Anything less than that causes a lag of operations due to inadequate power. However, never charge the battery for more than 30 hours.

- The vehicle is overloaded – Another reason for the sluggish movement of a power wheel may be due to overload. Every power wheel’s user manual comes with the minimum weight requirements.

Exceeding that weight limit leads to overworking of the mortars, and the result is the slow movement. In worse cases, the excess weight might lead to overheating the mortars, which might bring the ride-on to a complete stop.

To solve this, it is advisable to always stay within the car’s specified weight limit, and if possible, not tow anything behind the power wheel.

- The battery is old and won’t accept full charge – Even with proper maintenance, your power wheel’s battery will still get old.

The lifespan of a ride-on car’s battery is estimated to be around 1-3 years, depending on the model and frequency of use.

After that, the battery starts to develop complications, and one of them is that it won’t accept full charge. It is recommended that you get a replacement battery with an in-built thermal fuse.

- Battery needs charging – The most obvious cause of sluggish movement in a power wheel is low charge. Consider charging your battery to full charge before using it.

Only One Rear Wheel Spins When Pedal Is Pressed

When you encounter such a problem, it might be due to the vehicle’s operation at low speed. You’ll need to lift the rear of the car and press the foot pedal to inspect the proper operation of the drive system.

If you only have one rear wheel spinning, carefully press your hand on it to slow it down. If there’s not a big problem with the vehicle, then the other wheel should start spinning.

If that is not the case, it is clear that there may be a big problem with the power wheel.

Vehicle Only Runs in Low Speed

Some power wheels come with a high-speed lock-out for protecting the kids against the dangers of overspeeding.

If you notice that your recently acquired power wheel only moves at slow speeds, then the high-speed lock-out might not be disconnected.

If you need the ride-on to move at high speeds, then it is advised that you follow the vehicle’s manual to disconnect the high-speed lock-out.

In the ‘Operation Section’ of the manual, you’ll get a step-wise procedure on how to get rid of the high-speed lock-out screw.

NB: Most power wheel vehicles are designed to only operate at low speeds in reverse mode.

The Vehicle Won’t Run Without a Push

There may be two reasons why you are experiencing such a problem. One, it might be a loose wire or connector, and two, you may have a ‘dead spot’ on your motor.

To diagnose the problem, you need to check all the wires and connectors around the motor to ensure that they are a perfect fit. Also, inspect every other electrical component of the power wheel to ascertain the root cause of the trouble.

If you find that the problem lies in the motor, then there are slim chances of correcting it by yourself.

Power Wheel Maintenance Steps

- Ensuring that you follow all assembly instructions when performing the initial setup. You should assign two to three hours to assembly to make sure that the process is entirely error-free.

By doing that, then you’ll have evaded a load of future troubles that may be brought about by improper assembly. - Ensure that the power wheel’s battery is fully charged before use. That can be done by assigning 14-hour charging periods to make sure the batteries are fully charged.

If you find the ride-on discharging quicker than it used to be in the past, then check out the battery’s health. It might not be charging appropriately. - Ensure that the power wheel is ridden for at least 2-3 hours. Several factors impact riding time, including the riding surface, passenger weight, battery charge levels, frequency of use of the power wheel, overall condition of connectors, riding speed, and external temperatures.

- Take proper care of your batteries. If properly maintained, power wheel batteries last around two to three years before you can replace them.

- Always keep your charger in good condition. Constantly check it out for malfunctions, and if you find something, consider having it repaired or completely replaced if need be.

- Always have the power wheel kept in a protective environment, for instance, when raining or in snowy weather. Moreover, don’t leave the power wheels out in the sun for long periods as the UV may make the plastic brittle.

- During cleaning, it is advised to use a soft and dry cloth. If you need to give it a shiny look, use non-wax furniture polish to get the job done.

Avoid using automotive wax for the same. Again, avoid cleaning the power wheels with hard detergents and soaps, and strong water jets.

All these might result in fading of the ride-on’s paint. In the event the paint fades or chips off, you might need to repaint the whole thing. - Always make sure all nuts, bolts, and screws are tight before using the power wheels. Loosely fixed nuts and bolts leave weak points that may become sources of wear and tear.

- Check all screws and tighten them as required. Read the user’s manual to determine which screw should be hand-tightened and which should be tightened using a screw. Also, check on their protective coverings, to make sure they’re intact.

- Don’t keep your battery uncharged for long periods. That may lead to permanent damage. Therefore, it is imperative that you frequently re-charge your battery to preserve its power-holding properties.

- It is recommended that you take your car for regular checkup from authorized power wheel dealers to make sure that it does not harbor hidden complications.

- Safety is key. After modifying your power wheel from 6V to 12V, the new speeds may be challenging to handle for your kids. Consider teaching them how to drive at manageable speeds, and let them always put on protective clothing.

It is a recommended maintenance practice measure to regularly check your power wheel for faults, especially when it is more than a year old.

Check and re-check the state of the controllers, batteries, switches, mortars, and any other area prone to wear. That helps you quickly identify areas of the problem without waiting for the car to break down completely.

You also get to notice parts that may wear out and start preparing for their repair.

Conclusion

For convenience in repair, you need to perform these procedures in a clean, spaced-out space.

You can solve almost any of the Power Wheels’ problems and faults without having to purchase new ones. The solutions to most problems are easy to carry out, and you may solve them without taking them to specialists.

You’ll only need simple tools and a couple of minutes to get you through.

Again, it is not obvious that you face the issues highlighted in this article.

You should, therefore, always refer to the User’s Manual because it also gives a handful of solutions to prevalent problems that you’ll face that are related to that specific power wheel.